The B2B Buyer’s Guide to tattoo ink and supplies

- The B2B Buyer’s Guide to Tattoo Ink and Supplies

- Why Choosing the Right Tattoo Ink and Supplies Matters

- Business-intent keywords: wholesale tattoo ink, supplier reliability

- Understand Regulatory Landscape and Safety Requirements

- What to request from suppliers

- Core Product Categories for B2B Purchases

- Semi-permanent makeup inks

- Tattoo machines and wireless devices

- Consumables and practice supplies

- Supplier Evaluation Checklist

- Company credentials and history

- Quality systems and testing

- Regulatory compliance and materials sourcing

- Production capabilities: private labeling and OEM

- Price vs. Value: Negotiating Wholesale and Bulk Orders

- Volume discounts and MOQs

- Payment terms and logistics

- Quality Assurance: Testing, Shelf Life, and Storage

- Stability and expiry

- Cold chain and temperature control

- Packaging, Labeling, and Private Label Opportunities

- What to include on labels

- Training, After-Sales Support, and Warranty

- Technical documents and training kits

- Managing Risk: Insurance, Recall Readiness, and Crisis Response

- Supplier audits and traceability

- How to Build a Strategic Sourcing Plan

- Steps to build the plan

- Why Partnering with a Full-Service Manufacturer Helps

- Advantages for B2B buyers

- Conclusion: Make Decisions That Protect Clients and Grow Your Business

- Frequently Asked Questions

The B2B Buyer’s Guide to Tattoo Ink and Supplies

As a buyer in the semi-permanent makeup and eyelash tattoo industry, your decisions about tattoo ink and supplies affect client safety, brand reputation, and margins. This guide helps B2B buyers — salons, distributors, private-label brands, and training academies — evaluate products, vet suppliers, and create a sourcing strategy that balances quality, compliance, and profitability.

Why Choosing the Right Tattoo Ink and Supplies Matters

High-quality tattoo ink and supplies reduce infection risk, improve retention and color stability, and protect your business from regulatory and reputational issues. Investing in reliable supplies can lower rework and liability while increasing customer satisfaction and referral rates.

Business-intent keywords: wholesale tattoo ink, supplier reliability

Understand Regulatory Landscape and Safety Requirements

Regulations for tattoo ink and pigments vary by region. In the U.S., the FDA has authority over color additives but historically has not approved color additives for injection into human skin; the agency has increased scrutiny and issued guidance on impurities and toxic elements. In the EU, REACH and cosmetic regulations restrict certain substances used in pigments. Many reputable manufacturers follow international standards and third-party testing to verify heavy metals, microbial purity, and product stability.

What to request from suppliers

Request Certificates of Analysis (CoA), heavy metal testing (lead, arsenic, mercury, cadmium), microbial test results (absence of Staphylococcus aureus, Pseudomonas aeruginosa), and stability/shelf-life data. For private-labeling, ask for batch traceability and material safety data sheets (MSDS).

Core Product Categories for B2B Purchases

Understanding each category helps you build the right product mix for your clients or customers.

Semi-permanent makeup inks

Semi-permanent makeup (PMU) inks are formulated for brows, lips, and eyeliner. Look for pigments designed for minimal migration, consistent particle size, and predictable fading characteristics.

Tattoo machines and wireless devices

Wireless tattoo machines and microblading devices should offer consistent needle stroke, adjustable speed, and battery life suitable for professional use. Consider warranties and replacement parts availability.

Consumables and practice supplies

Include tattoo skin for practice, numbing creams, sterile needles/cartridges, tattoo inks, pigments, and approved aftercare products. Stocking reliable consumables ensures uninterrupted services and training.

Supplier Evaluation Checklist

Use this checklist when evaluating potential suppliers of tattoo ink and supplies to minimize supply chain risk and protect your clients.

Company credentials and history

Confirm manufacturer history, production capacity, and facilities. QM Makeup, for example, was established in 2005 and operates a 10,000 square meter production base with R&D and OEM capabilities — a model to look for in reliable suppliers.

Quality systems and testing

Verify ISO certifications, internal quality control processes, CoAs, and third-party laboratory testing. Ask about in-house microbial testing and batch release criteria.

Regulatory compliance and materials sourcing

Ask whether pigments comply with regional rules (REACH in EU, applicable guidance in the U.S., and restrictions in other markets). Confirm raw material traceability and whether pigments are vegan/cruelty-free if that’s a market requirement.

Production capabilities: private labeling and OEM

For B2B brands looking to scale, evaluate the supplier’s OEM and private label manufacturing minimums, lead times, and customization options. A production partner that supports custom formulations, labeling, and packaging can accelerate market entry and protect margins.

Price vs. Value: Negotiating Wholesale and Bulk Orders

Price is important, but quality and reliability determine long-term value. Negotiate based on order volume, lead times, payment terms, and bundled services like private labeling or marketing materials.

Volume discounts and MOQs

Request tiered pricing and understand minimum order quantities (MOQs). Many manufacturers offer better per-unit pricing at higher volumes; balance carrying costs against unit cost savings.

Payment terms and logistics

Negotiate payment terms (e.g., 30/70 split, NET30), shipping options (FOB, CIF), and lead time guarantees. For international shipments, ensure correct HS codes and understand duties and import regulations for tattoo ink and supplies.

Quality Assurance: Testing, Shelf Life, and Storage

Proper storage and shelf-life management maintain product efficacy. Implement a first-expire-first-out (FEFO) system and maintain storage conditions recommended by the manufacturer (temperature, light exposure).

Stability and expiry

Ask suppliers for stability studies showing pigment performance over time and under various conditions. Typical shelf life for many inks is 2–3 years when unopened; opened products often have a shorter recommended use period.

Cold chain and temperature control

Some pigments benefit from cool, stable storage. If transporting in hot climates, consider refrigerated logistics to protect product integrity.

Packaging, Labeling, and Private Label Opportunities

Private labeling is a common growth strategy for B2B buyers. Evaluate supplier capabilities for custom packaging, compliance labeling, multilingual inserts, and barcoding for inventory control.

What to include on labels

Labels should include ingredients, lot number, production and expiry dates, storage instructions, batch CoA reference, and safety warnings. For EU markets, include mandated labeling elements per local regulations.

Training, After-Sales Support, and Warranty

Good suppliers provide technical support, usage guidelines, and training materials — especially helpful for salons and academies that productize training services. Warranty and replacement policies for devices are also critical.

Technical documents and training kits

Request vendor manuals, troubleshooting guides, practice skins, and starter kits for students or new staff. These materials reduce onboarding time and support consistent service delivery.

Managing Risk: Insurance, Recall Readiness, and Crisis Response

Ensure your supplier has product liability insurance and documented recall procedures. Agree on recall communication responsibilities and replacement/compensation terms before signing contracts.

Supplier audits and traceability

Perform supplier audits (onsite or virtual) focusing on cleanliness, batch control, and documentation. Maintain batch traceability in your own inventory system to enable quick action if an issue arises.

How to Build a Strategic Sourcing Plan

Create a sourcing plan that matches risk tolerance, business model, and growth objectives.

Steps to build the plan

- Map product categories and prioritize by sales volume and risk.

- Define minimum quality requirements (CoA, microbial, heavy metals).

- Identify 2–3 vetted suppliers for each core SKU to ensure redundancy.

- Negotiate scalable pricing with performance KPIs and SLAs.

- Implement incoming QC checks and a supplier scorecard for continuous evaluation.

Why Partnering with a Full-Service Manufacturer Helps

Partnering with a manufacturer that offers distribution, wholesale, private labeling, and OEM — like QM Makeup — streamlines supply chains. A single partner with R&D and production capabilities reduces lead times for custom formulations and supports brand consistency across product lines.

Advantages for B2B buyers

Centralized production, faster product development, lower minimums for private label through negotiated MOQs, and consolidated compliance documentation help you scale efficiently.

Conclusion: Make Decisions That Protect Clients and Grow Your Business

When buying tattoo ink and supplies, prioritize verified quality, regulatory transparency, and supplier reliability. Use testing documentation, supplier audits, and supplier scorecards to manage risk. Consider suppliers that offer private labeling and OEM services to accelerate growth. A strategic, data-driven approach ensures you protect clients while building a profitable B2B business in semi-permanent makeup.

Frequently Asked Questions

Q: What documents should I always request from a tattoo ink supplier?A: Request Certificate of Analysis (CoA) for each batch, heavy metal and microbial test results, Material Safety Data Sheet (MSDS), shelf-life/stability data, and evidence of manufacturing standards (e.g., ISO certificates). These documents help verify product safety and traceability.

Q: Are tattoo inks regulated by the FDA?A: The FDA has authority over color additives and can regulate tattoo inks, but historically many inks have not been specifically approved for injection into skin. The agency has increased scrutiny and guidance; reputable suppliers provide testing and compliance documentation to reduce regulatory risk.

Q: How do I choose between multiple suppliers who claim ‘medical-grade’ inks?A: Compare third-party test results, batch traceability, production facility audits, and the supplier’s willingness to provide supporting documentation. Check references from other B2B customers and request sample batches for internal testing before committing to large purchases.

Q: What minimum inventory levels should a B2B buyer keep?A: Inventory depends on sales volume and lead times. A common approach is to maintain 1–3 months of buffer stock for top-selling SKUs and have alternate suppliers for critical items to avoid stockouts.

Q: Can I private-label tattoo inks and supplies?A: Yes. Many manufacturers offer private-label and OEM services. Confirm MOQ, labeling compliance for target markets, and the partner’s capability for custom formulation and packaging.

Q: How should tattoo ink and supplies be stored?A: Store inks in a cool, dry, and dark environment, following supplier guidance. Use FEFO (first-expire-first-out) for inventory rotation, and avoid temperature extremes during shipping to preserve product integrity.

Q: What are the signs of inferior tattoo ink?A: Signs include inconsistent color, rapid fading or unpredictable migration, strong chemical odors, sediment that won’t re-suspend, and adverse client reactions. Insist on testing and small pilot batches to validate performance.

Q: How can a B2B buyer reduce liability when sourcing supplies?A: Work with reputable suppliers who provide CoAs, carry product liability insurance, and have traceability. Maintain professional training standards, informed consent protocols, and document supplier communications and batch usage in client records.

Best Numb Tattoo Cream for Semi Permanent Makeup: Super Numb

Sustainable Materials in Microblading Tools: Buyer Guide

Top Ingredients in Microblading Eyebrow Pen Pigments

Top liner tattoo needle Manufacturers and Suppliers

Customized service

Are there any additional charges for customized services?

Customized services may be subject to appropriate customization fees based on your specific requirements, which can be negotiated with our sales team.

Pigment Ink

What is the MOQ for customization ?

For label customization, the MOQ is 100pcs; for packaging customization, the MOQ is 1000pcs; for other in-depth customization, the MOQ will be based on your specific requirements.

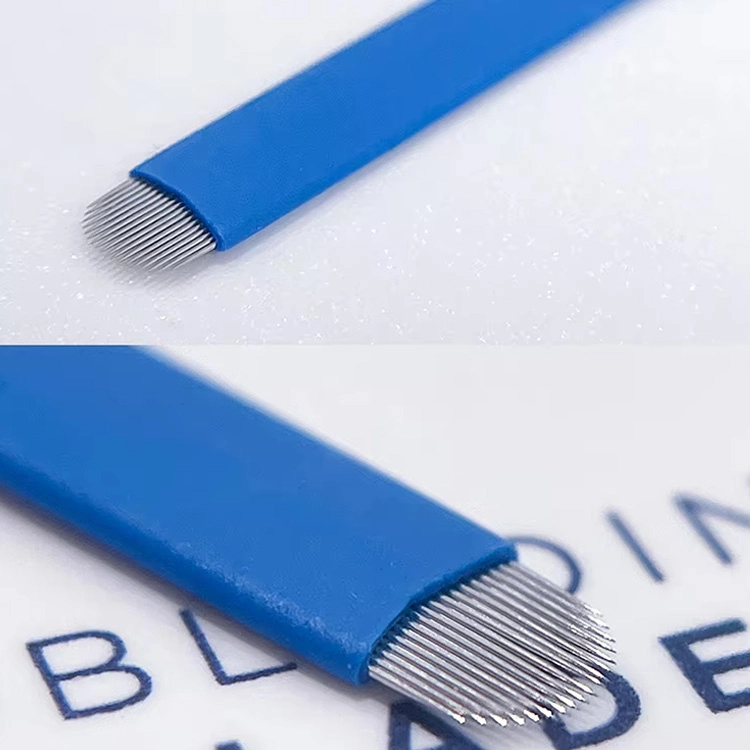

Micro Blade

Do your microblades contain nickel?

Our flex microblading needle are made of 304 stainless steel, which does contain traces of nickel. The addition of nickel can can enhance the corrosion resistance of stainless steel and increase its toughness and strength, ensuring that the material will perform consistently in a variety of environments. Since the microblades are only implanted through the skin, there is no adverse reaction to the skin under normal circumstances. If you are concerned about this, a patch test can be performed prior to the procedure.

Tattoo Numbing Patches

How many percentage of the numbing can be reach?

Our mature and stable numbing formulas typically achieve more than 90% numbing effects. It can keep numbing effect last for 3-4 hours.

Eyelash curling

Can customers with sensitive skin or eyes use lash perm kit?

For customers with sensitive skin or eyes, it is recommended that a patch test be performed prior to use lash lift perm kit. However, our formula is relatively mild and anti-allergenic, so it is normally non-allergenic and suitable for most people.

Professional Pre Inked Eye Brow Mapping String 30m

Microblading Pre-inked Mapping String Line 10m

Nano Brows Numb Cream For Tattoo

Instagram

Facebook

YouTube